MAKING AND MACHINING OF GLASS

GALIOPTIC makes mineral glass pieces for different business sectors : medical, research, aeronautics, industry, defence, architecture, decoration ...

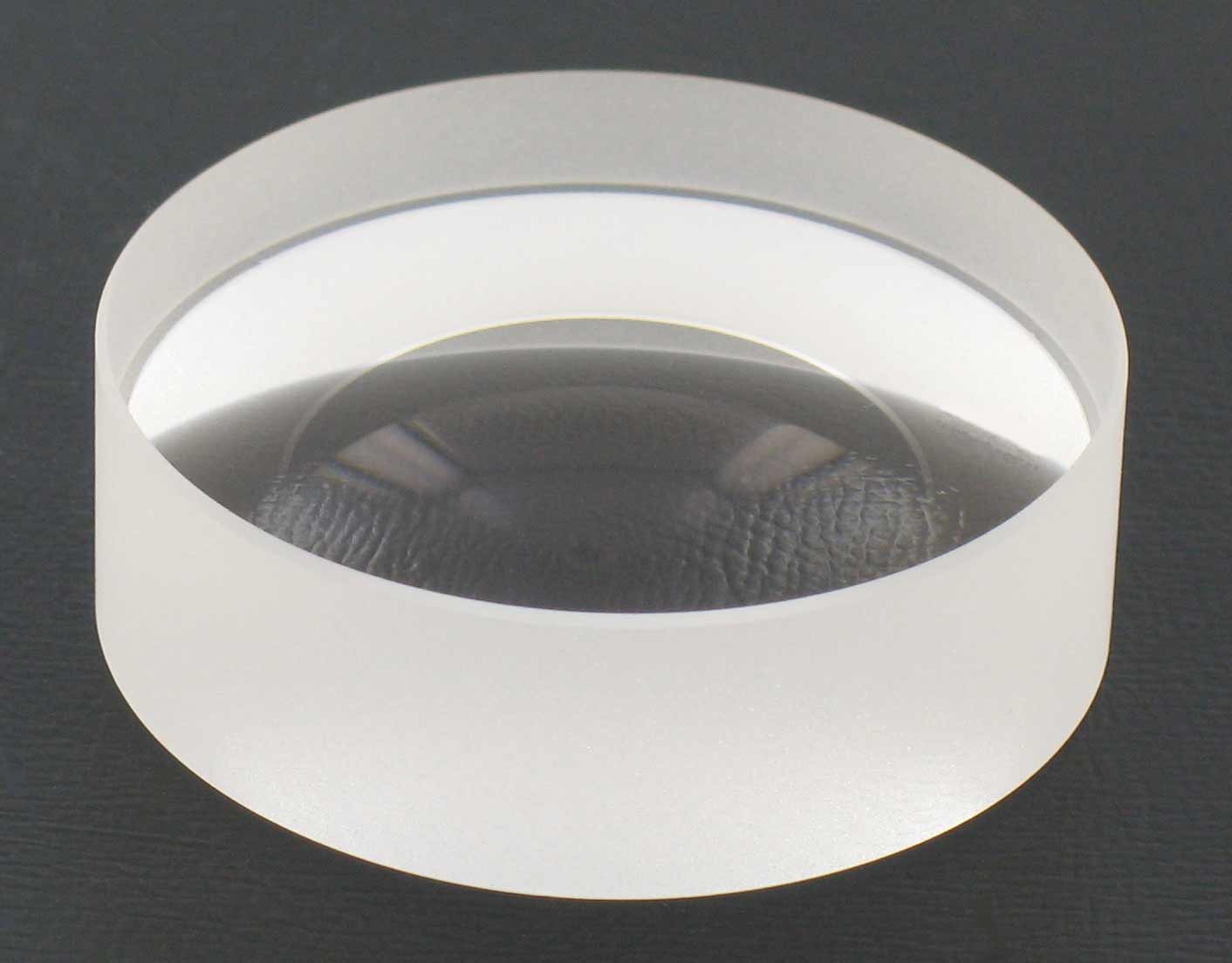

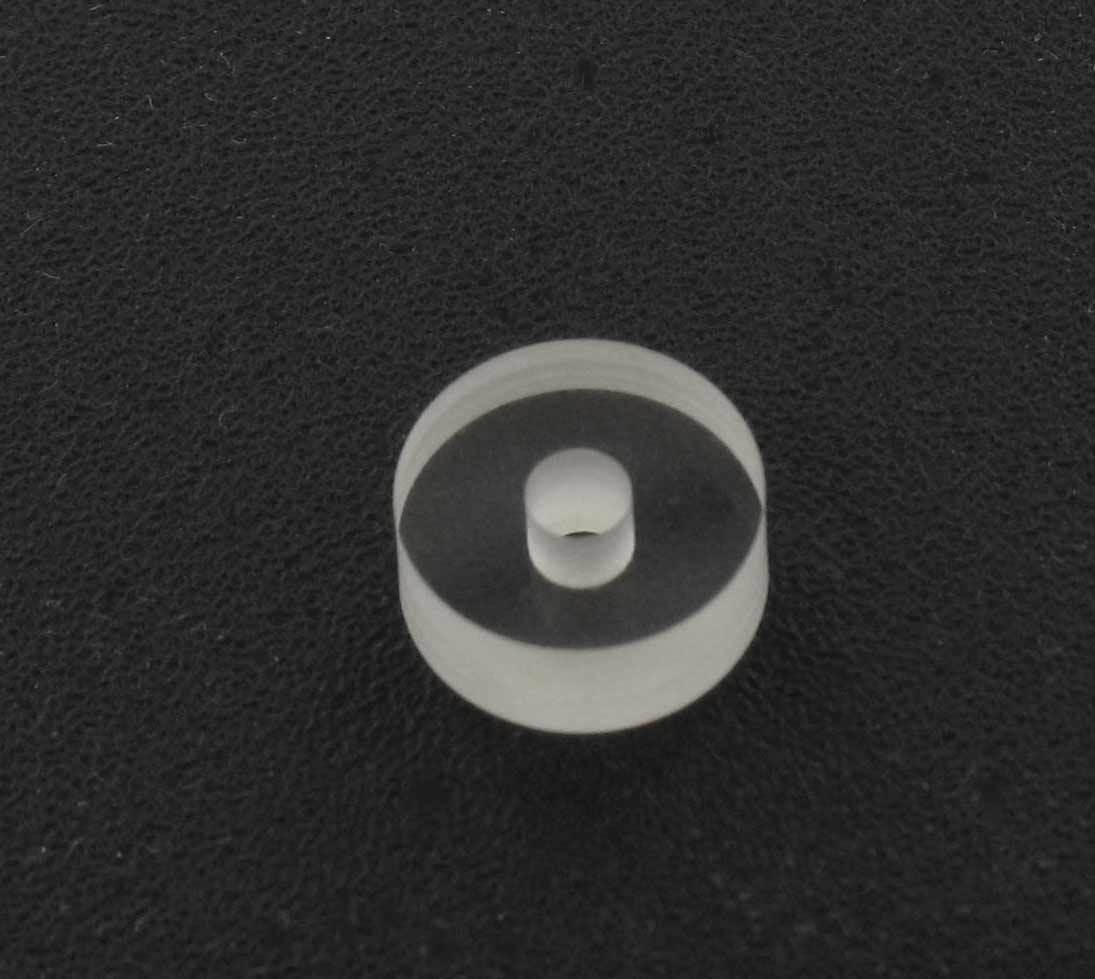

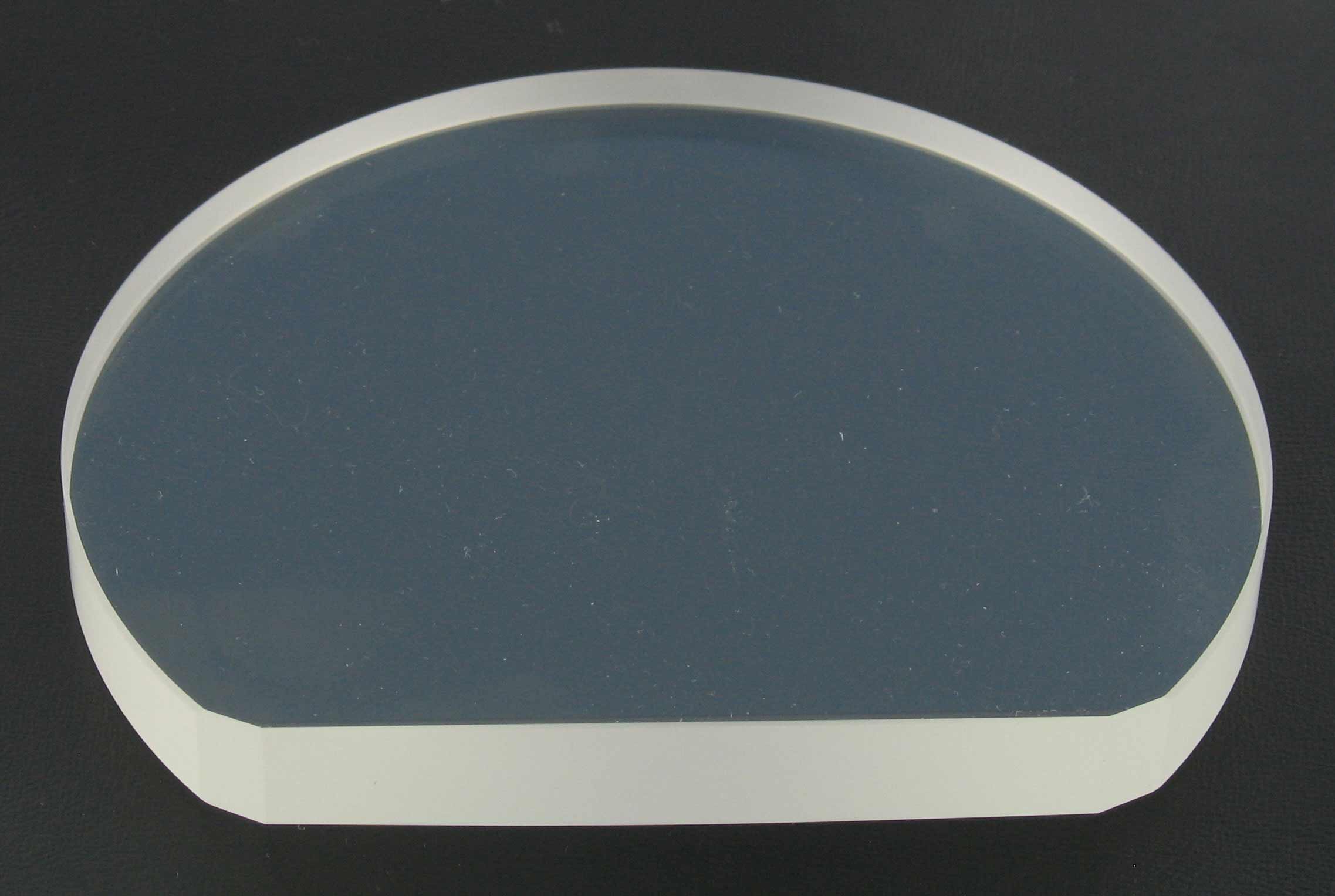

The glass is manufactured either from a raw material or from a rough shape, or pressed-molded in high temperature ovens.

Various operations allow then to obtain the desired characteristics : quality of the shine and roughness, precision of the dimensions, optical sticking, molecular adherence, surface treatment.

From the prototype to the series, up to several thousand pieces a week, GALIOPTIC offers a big choice to companies and solutions in several domains.

GALIOPTIC is able to mark pieces (name, logo, numbering...).

POLISSAGE DE PRECISION

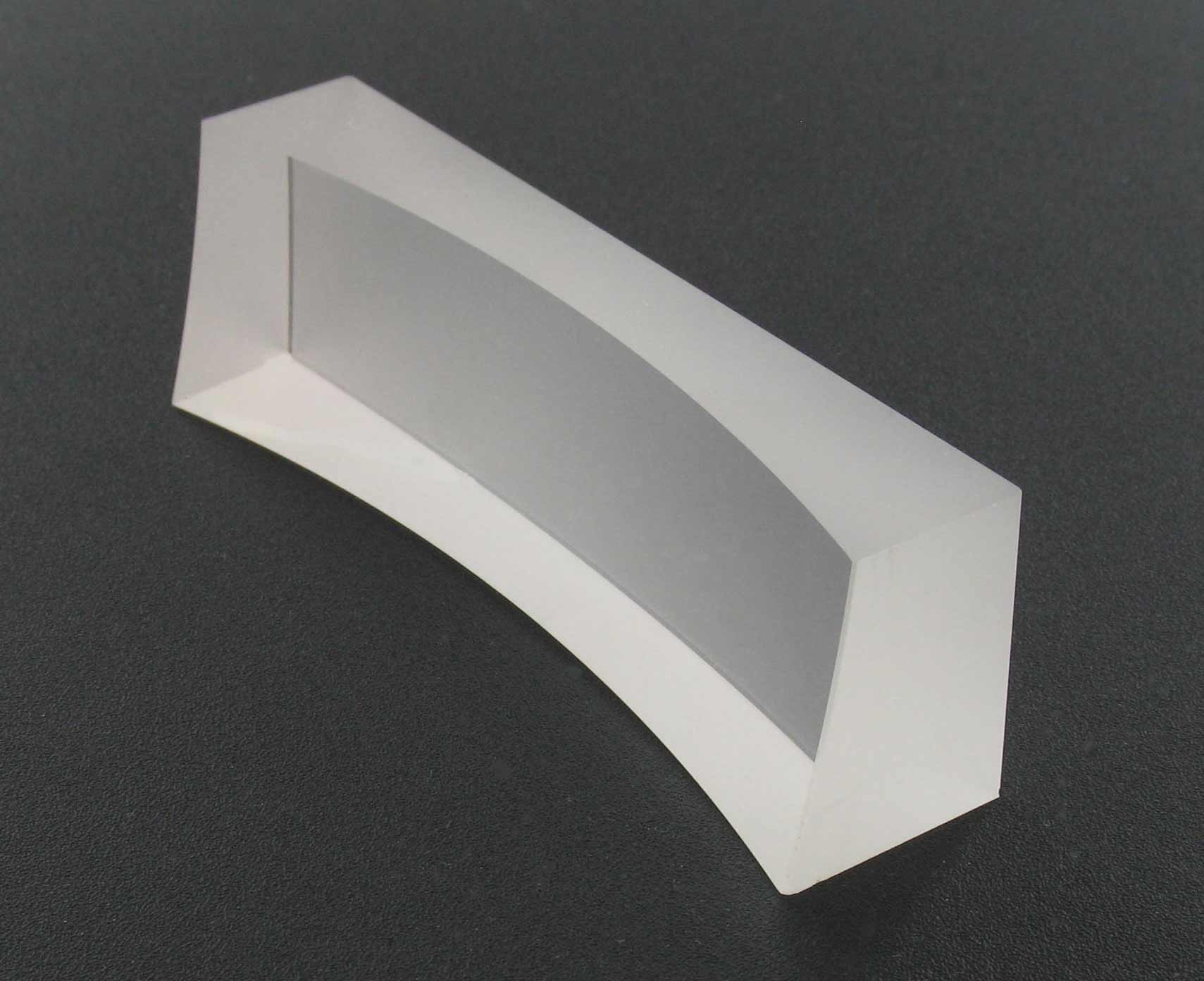

In the workshop, a highly qualified staff takes care of the manufacturing of complex optical components.

With polishing and specific control equipments, GALIOPTIC is one of the french workshops able to respect high levels of precision.

Its productions make GALIOPTIC a big partner of research centers, high technology industries in France and Europe.

GALIOPTIC realizes 30% of its turnover in the export market.

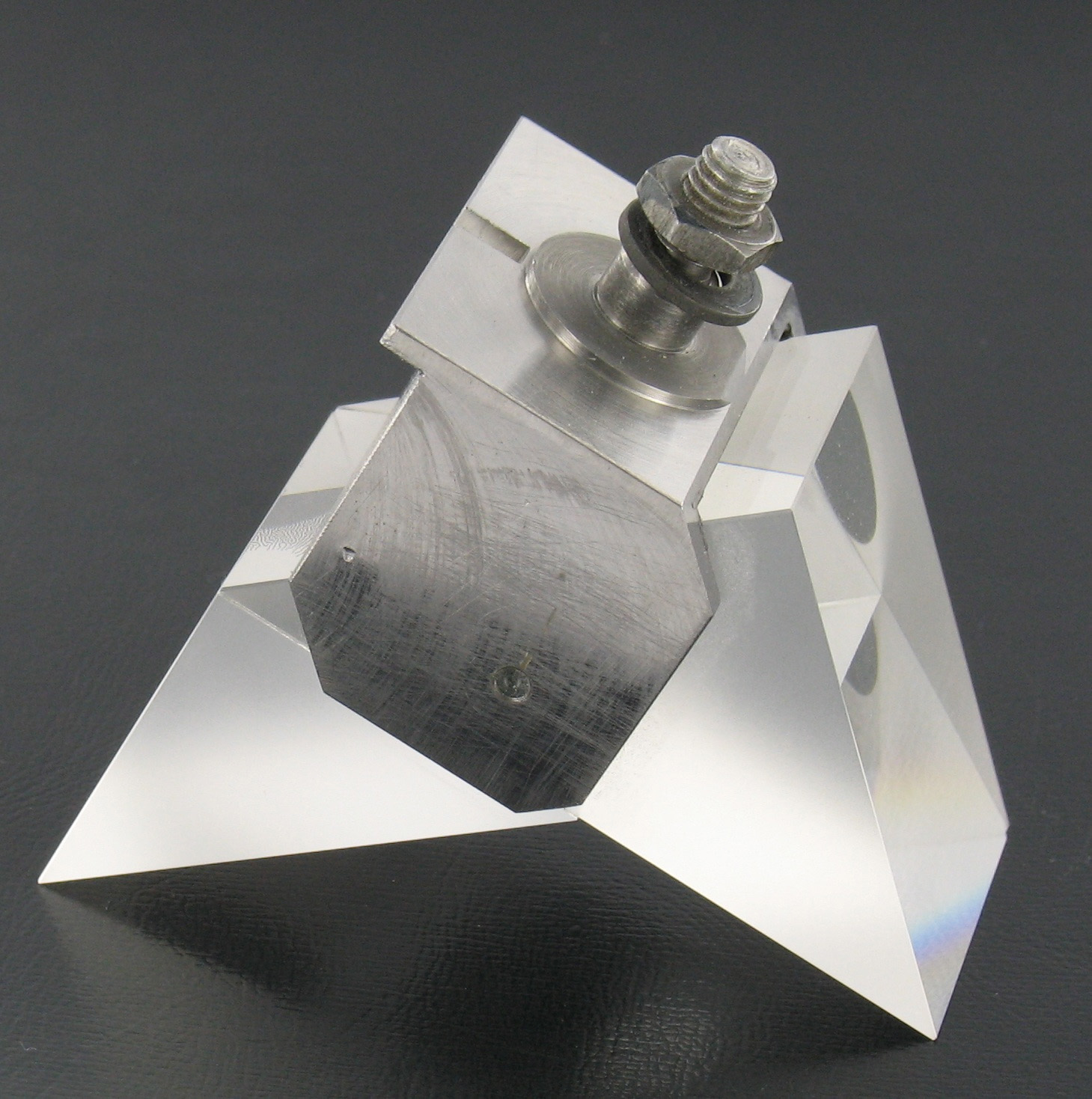

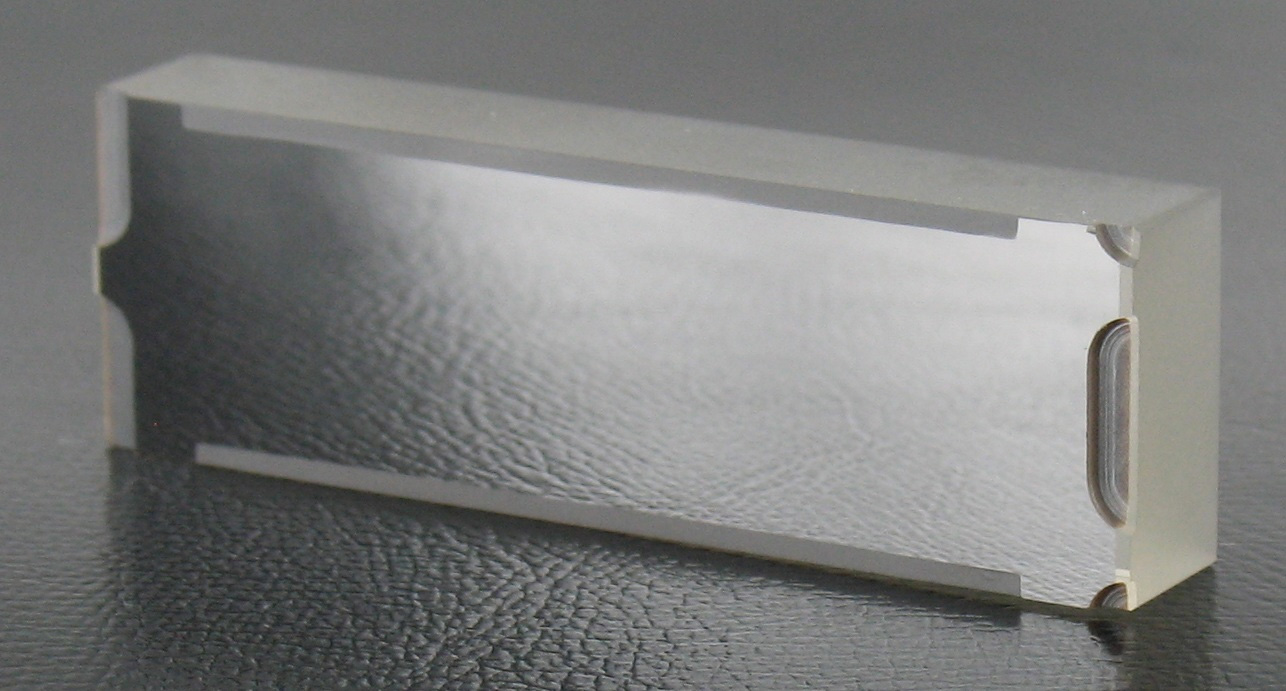

In the case of manufacturing of optomechanical systems, GALIOPTIC carries out in-house the manufacturing of the mechanical pieces (Stainless stell, Aluminium, Brass, Copper, Lead, Tin...).

GALIOPTIC works in partnership with companies specialized in precision mechanics and surface treatment :

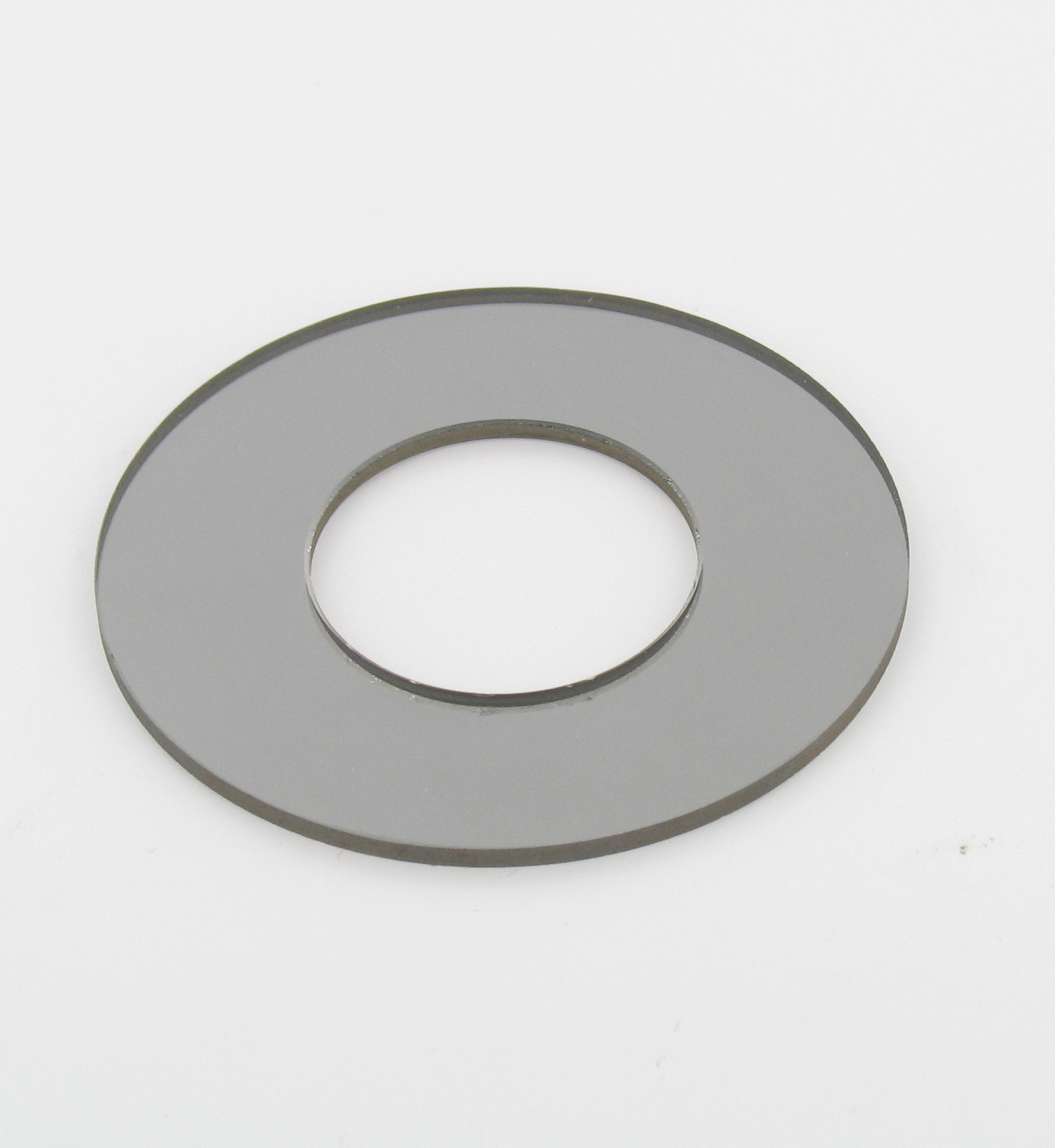

Application of thin layer in spectral band from 175 to 3 300 nm.

Metallization by process PVD (Physical Vapor Deposition) : Aluminium, Sliver, Gold, Chrome, Nickel, Platinum, Graphite carbon...)

Spectrometric line